When it comes to the manufacturing world, time is money. That means efficiency is key, and CNC milling solutions are the ideal choice for quick turnaround on precision machined parts. Used within a variety of industries, CNC milling is perfect for enhancing efficiency without sacrificing quality. Let’s dive into this process and its benefits in more detail.

MultiSource Manufacturing is ready to elevate the standard of your precision machined components. Connect with us today to get started.

A Closer Look at CNC Milling

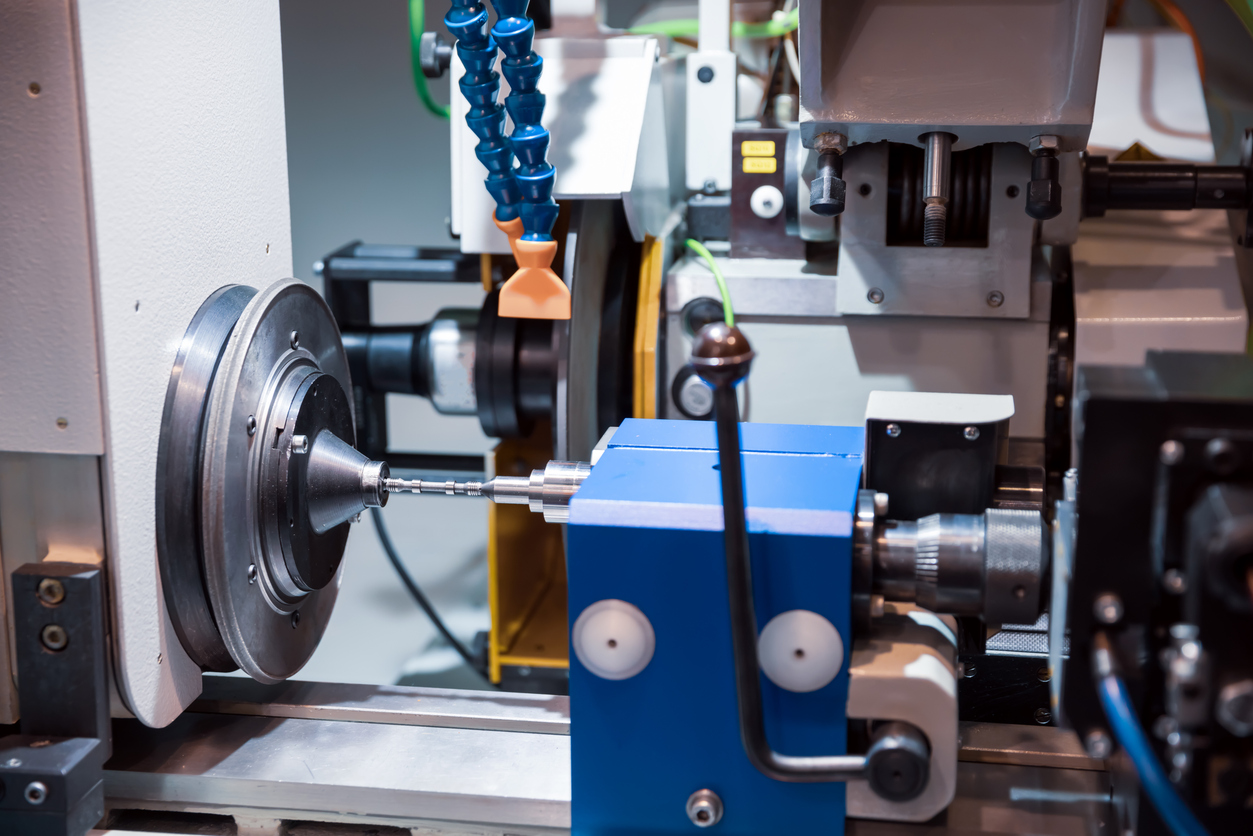

First, it’s important to examine the CNC milling process to understand its advantages. CNC milling is a subtractive process that uses computer controlled equipment to direct rotating cutting tools to remove material from a part until it reaches the desired dimensions and shape.

You can expect to find CNC milled parts in a variety of industries, such as:

- Aerospace and Defense: landing gear components and weapons parts

- Medical: surgical instruments and medical devices

- Semiconductor: microchip reticle handling equipment and wet processing products

- Industrial: computer or electronic components and agricultural parts

CNC milling is different from another precision machining process, CNC turning. While this is another subtractive process, CNC turning involves a part rotating on a lathe while a cutting tool removes material in order to craft a cylindrical piece. Swiss machining also differs from CNC milling. This manufacturing method uses a specialized lathe to create small, intricate parts with tight tolerances. While all of these precision machining processes produce quality parts, there are certain specific advantages that CNC milling solutions offer. Let’s take a closer look at them.

Enhanced Quality, Optimized Costs: The Advantages of CNC Milling Solutions

Expect improved product performance from CNC milling. This process enhances accuracy and allows the production of parts with extremely precise measurements, boosting quality and ensuring that components function as required.

CNC milling is also suitable for automation. That means CNC mills can be programmed to run non-stop if needed, increasing efficiency and resulting in faster production times. Because of this, you should also consider CNC milling solutions for your high-volume production needs.

This manufacturing method crafts consistent and reliable components, and because of this enhanced precision, you can also expect a reduced need for reworks or replacements. This means you’ll don’t need to worry about excess material or labor costs, or time-consuming delays. Instead, you can expect a higher standard of quality that will lead to greater customer satisfaction.

Trust MultiSource for Best-in-Class CNC Milling Solutions

At MultiSource Manufacturing, CNC milling is our expertise. We have a range of high-tech 3-, 4-, and 5-axis milling machines, and have the capabilities to provide for your low- or high-volume production needs. Our experience involves multiple industries, and we are able to work with a variety of materials, like aluminum, copper, stainless steel alloys, and more.

Our commitment to quality is obvious. We have a number of important certifications, including ISO 9001:2015, ISO 13485:2016, and AS9100 D. With our strong relationships with expert sub-tier suppliers, we are able to streamline the manufacturing process and provide our customers with exceptional CNC milling solutions. Get in touch with MultiSource today to see how we can help you raise the standard of your components.