In the precision machining world, there are numerous processes that are used in order to craft accurate and consistent products. Perhaps one of the most effective and popular methods is Swiss machining. Swiss machined parts offer many valuable benefits, and are used within a large variety of industries. These parts are reliable and precise, performing as required in any application. Here, we will take a closer look at how Swiss machined parts can elevate the quality of your next product.

Don’t wait to boost your Swiss machined components — reach out to MultiSource Manufacturing today to get started.

Understanding the Swiss Machining Process

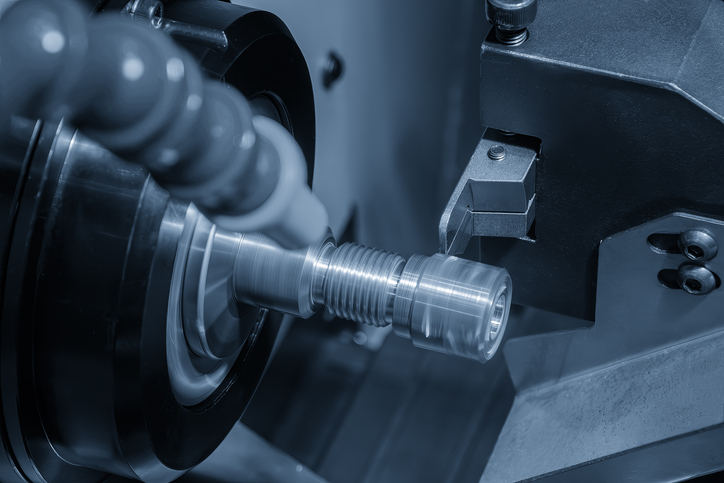

First, it’s important to understand how the Swiss machining process works. With this manufacturing method, a specialized cutting tool, a Swiss-designed CNC lathe, works on material while it turns. It then cuts the workpiece until it reaches its desired shape.

This process is different from regular CNC lathe manufacturing, which is another popular precision machining method. In Swiss machining, the material can spin and move back and forth, which means that several tools can work on it at the same time. This is ideal for smaller, intricate parts. A CNC lathe cuts material while the workpiece is typically rotated in a fixed position, making it a useful tool for larger components.

The Benefits of Utilizing Swiss Machined Parts

Swiss machining can offer many enticing advantages. For instance, this process creates very precise parts, which is important for a variety of critical industries. Swiss machining supports the workpiece as it turns, eliminating excess vibration and ensuring accuracy. It also produces components with extremely tight tolerances. This is essential for products that require exacting standards and help ensure those products perform as needed.

In addition, Swiss machining results in faster production times. It is well-suited for automation, which means Swiss machined parts can be produced quickly and efficiently. This also means that this manufacturing process is suitable for high-volume production.

Because of the consistent quality of these Swiss machined components, you can also expect reduced costs. There’s a lower need for reworks or replacements, and material waste is decreased. Swiss machining also results in high quality surface finishes, leading to higher customer satisfaction.

Applications of Swiss Machined Parts

Swiss machining is an ideal manufacturing solution for a wide range of industries due to its ability to craft extremely precise components with tight tolerances. There are many mission-critical industries that have exacting standards in order to ensure parts function as required, and Swiss machining is the perfect precision machining process for those industries.

For instance, aerospace often utilizes Swiss machined parts for the reasons outlined above. These components are used for motors, wings, landing gear components for aircraft, and much more. This industry requires precision. Parts that don’t perform as expected would be disastrous, which is why Swiss machined parts are ideal.

Similarly, the defense industry uses Swiss machining because of its many advantages. It’s a perfect manufacturing process for the complex parts that are used in helicopters, military vehicles, weapons, and more vitally important products used for various defense applications.

You can also expect to find numerous Swiss machined parts in the medical industry. These components are used for surgical screws, implantable devices, and more. Durability and precision are a requirement in this industry, making Swiss machining an ideal choice for medical parts.

Trust MultiSource for Exceptional Swiss Machining

At MultiSource Manufacturing, we have a proven track record of excellence. We are experts in Swiss machining, and are capable of producing complex, intricate parts that require tight tolerances. Our high-tech equipment and efficient processes allow for shorter lead times and enhanced quality.

In addition to Swiss machining, our other precision machining capabilities are vast, and include CNC milling, CNC turning, wire EDM, fine finishing, complex grinding, assembly, and more. With our start-to-finish support, you can also expect exceptional secondary processes, like lasering and painting, to ensure your project is finished to perfection.

We also have strong relationships with sub-tier suppliers who enable us to provide you with specialized services. Quality is our top focus at MultiSource and we hold a variety of certifications to prove it. In addition to our ISO and AS certifications, we are NIST 800-171-compliant, and we adhere to DFARS and ITAR requirements. If you are looking for world-class Swiss machined parts, look no further. Get in touch with MultiSource today.